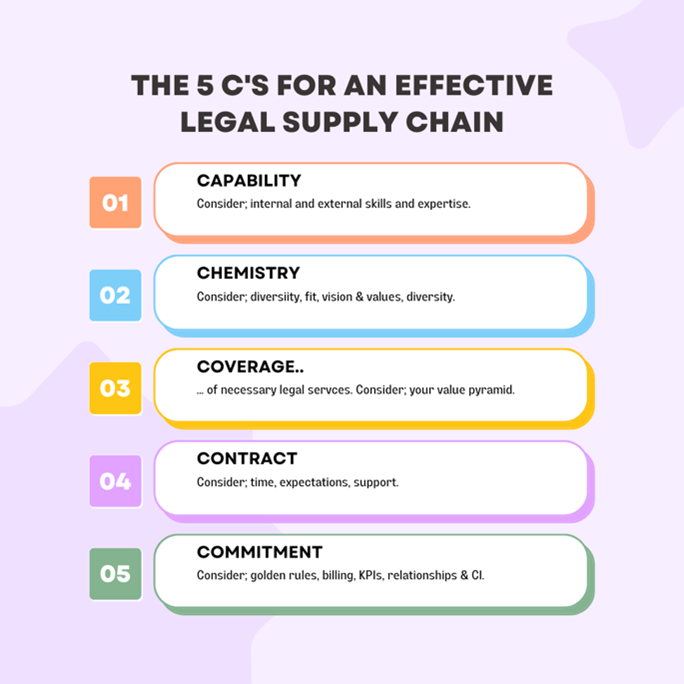

The 5Cs for an Effective Legal Supply Chain

As a General Counsel or Legal leader (GC), your supply chain can play an essential part in the delivery of legal services for your organisation. An effective legal supply chain is one that ensures a win-win for the legal function and the supplier; outputs are value-adding and fit for purpose in terms of costs, quality, and standards of service.

Moving from a transactional to a symbiotic and aligned relationship requires ongoing investment, but in our experience, focussing on the five core “C” s detailed here really creates the foundations of success.

What makes an effective legal supply chain?

1: Capability

Your supply chain can typically encompass legal, recruitment and technology providers delivering advice, goods and services that the internal legal function cannot undertake.

Being mindful of capability will ensure that the level of expertise and its practical application for your organisation is delivered at the correct costs, quality and delivery, enhancing the team's brand. Leading legal providers all have a capability level that would satisfy most requirements. However, the GC should test if: (1) they are over-paying for over-qualified resources on their account based on work complexity, (2) technical capability is not translating into business commercial, practical legal advice, and (3) capability detailed in RFP responses truly exists and where gaps are identified, and immediate action is taken.

Today, capability requires a blend of legal expertise and other skills such as project and programme management, creative problem solving and utilisation of technology and process management.

2: Chemistry

Not only are the correct skill sets (and their usage/application) important, but so is the “chemistry” in your supplier/customer relationship. In our opinion, chemistry manifests well when legal teams and suppliers invest time in understanding each other needs and expectations; suppliers proactively identify and solve client pain points and further their causes. Supply chains that have invested in LEX360’s effective customer programmes have the tools and infrastructure to be successful. A symbiotic and aligned relationship will drive effective working with minimal disruption, rework, conflict and misunderstanding, therefore driving efficiency and effective working.

In this instance, the definition of “chemistry” can also be extended to include a fit in terms of vision, values and ways of working. For example, companies with the same ethos and principles regarding diversity and sustainability are more likely to work well together in these areas based on similar understandings and ethics. A failure to consider your supply chain’s culture and how that fits into your culture will create misaligned outputs, approaches and attitudes towards the internal business and external customers.

3: Coverage

The next hurdle to overcome is ensuring that the supply chain complements the internal team in servicing the needs of the business and provides the additional coverage required regarding work packages or jurisdictional needs.

One of the first exercises LEX360 does on supply chain engagements is to help legal teams consider current and future work scenarios to identify coverage and capability needs for future work. A failure to effectively understand this may result in an ineffective supply chain which is either over or underpopulated. A supply chain that is not invested because they are not receiving throughput or detailed instructions will impact the relationship and outputs.

One of the models that we use to identify coverage and capability needs is the legal value pyramid, ensuring that the most appropriate individuals are aligned with the work-packages.

Another element to consider here is that forecasting as inaccurate or a lack of forecasting of upcoming work can lead to supplier unavailability or paying for time that is not used.

4: Contract

The selection of your suppliers is critical, and as such, a thorough and appropriate procurement process should be completed. This should ensure that your chosen parties can meet your requirements regarding the other 5C’s as well as costs, quality, and delivery obligations.

In our experience, the investment in the contracting stage from RFP to selection is often comprehensive, but when it comes to document commitments on both sides, this is sub-optimal. A failure to document commitments on both parties, including key performance indicators and the re-course process, can result in a breakdown of trust and, ultimately, a lose-lose situation, culminating in performance issues or contractual disagreements.

Items that should be negotiated and included in the contract include:

- Golden rules – these set out the “golden rules” in terms of expectations and ways of working for suppliers to align with, cascade within their teams and adhere to.

- Relationship management – regular meetings with clearly set agendas, expectations, and outcomes, such as reviews of management information, KPIs (Key Performance Indicators) and also two-way conversation and feedback.

- Billing Guidelines – this could link to your value pyramid and link to decision trees to drive appropriate work allocation and billing.

5: Commitment

The final “C” is commitment, which entails a mix of clear communication, continuous improvement and conflict resolution to ensure an efficient and successful supply chain.

Communication – creating a vehicle (relationship meetings, innovation teams, offsite days) where vital strategic issues are discussed and committed to. This is a channel to give feedback on performance, including the utilisation of non-delivering law firm partners. Law firms and the GC create the space of the ‘people at the coal face’ presenting solutions; nothing is worse than a senior partner poorly explaining a technology solution their firm has developed.

Conflict resolution – a process where adult conversations can happen and be resolved with the interest of sustaining the relationship. Problems are opportunities to do things better, so creating the conditions for planning, checking, and acting on solving these problems for the panel's success is key.

For further information on these topics, please visit LEX360.co.uk or email Mo and we will gladly help.